FRP Package Type Sewage Treatment Plants

Fibre Reinforced Plastic (FRP) Sewage Treatment Plants (STPs) are advance, corrosion-resistant and lightweight solutions for organic wastewater treatment. These are low-maintenance and eco-friendly systems which are installed underground to avoid wastage of expensive land bank and at the same time discharge water for various uses as per environmental standards.

Capacities: 10-250 KLD (and in multiples thereof for higher requirements).

Advantages

The most important advantages provided by package-type STPs are:

- Land Saver: These underground package-type STPs save wastage of expensive land. In other words, such STPs can be installed under a playground, under a parking space, under roads/pathways and in any such available space.

- Corrosion Resistant: FRP tanks do not rust, making them ideal for long-term wastewater treatment.

- Lightweight & Easy Installation: Up to 75% lighter than concrete tanks, simplifying transport and setup.

- Eco-Friendly & Energy Efficient: Reduces energy consumption and environmental pollution.

- Modular & Scalable Design: Suitable for small residential units to large industrial complexes.

- Minimal Maintenance: Requires less frequent cleaning and sludge removal than conventional STPs.

- No Foul Smell: These systems emit the least amount of foul smell in the surroundings compared to the conventional ones.

Working Principle

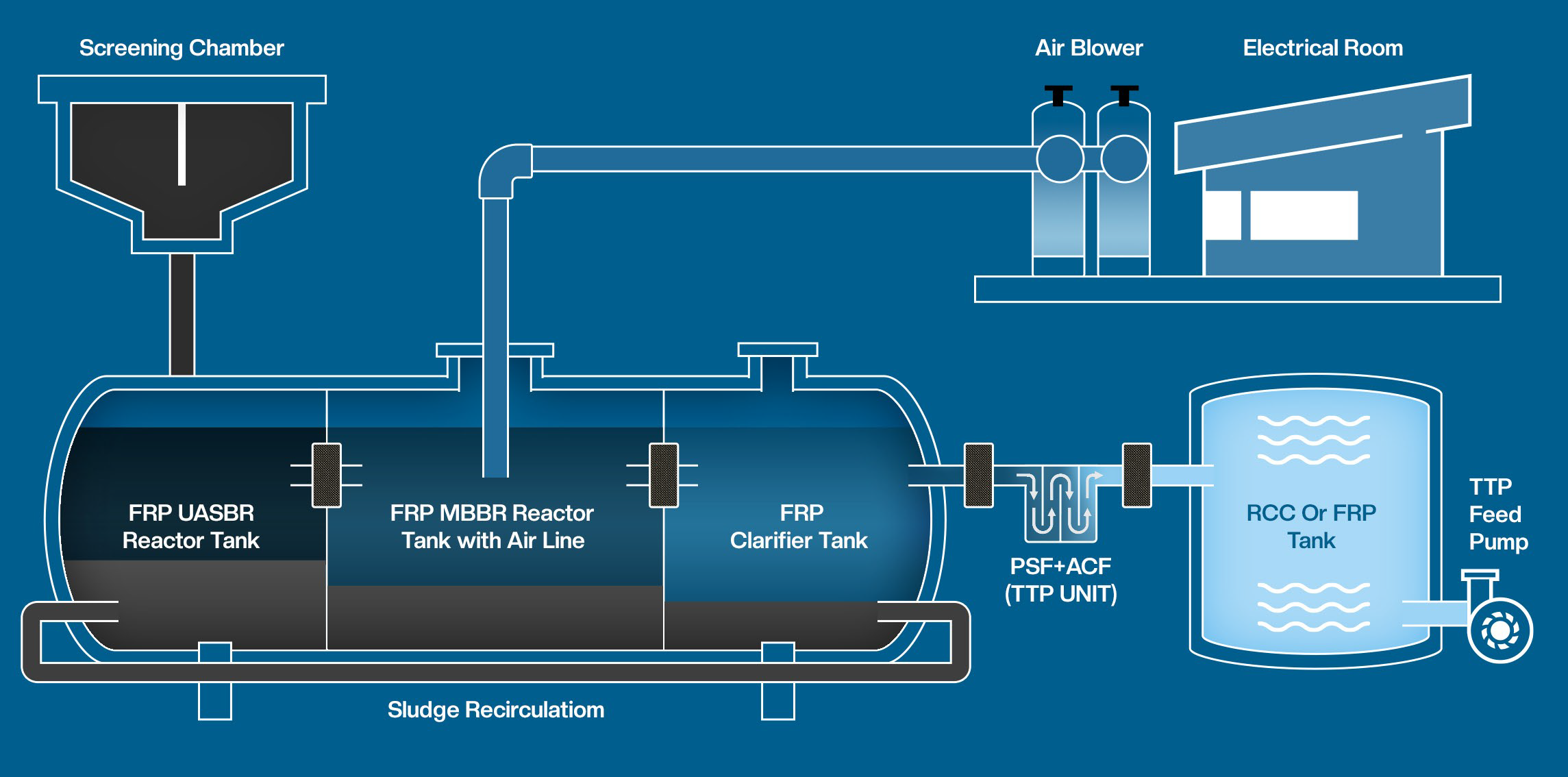

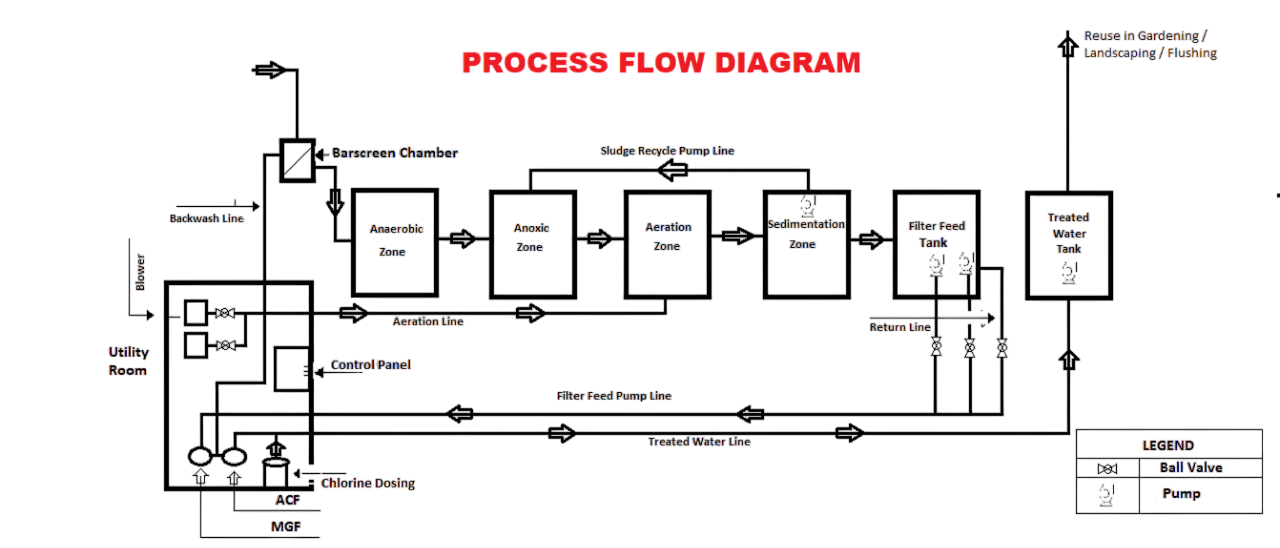

The components of a typical package-type STP are:

- Far Screening Chamber: Separates solid waste

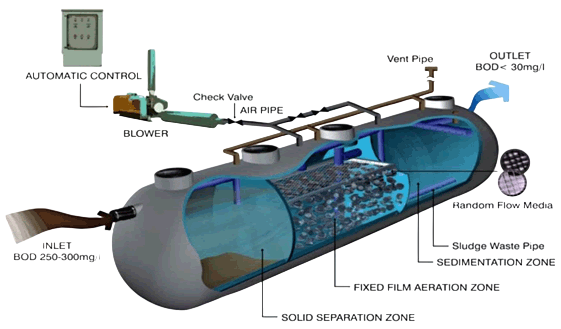

- UASBR Reactor: The first stage transforms influent solids to settled solids while allowing scum to float. It is a primary anoxic treatment zone in which the settled sludge is stabilised by anaerobic digestion.

- Aeration Zone (MBBR Reactor): The second stage is an aerobic zone with media inside the tank which increases the surface area to retain the microorganism long enough to digest the organic substances. Air is provided through blowers and higher contact time with the slime on the plastic media facilitates efficient digestion. Clear water overflows to the next treatment chamber.

- Clarifier Zone: The final stage involves sedimentation, where the organic waste that is settled down at the bottom of the tank is pumped back to the solid separation zone. The settled waste in the bottom of the tank is pumped back to the Solid Separation Zone as a return sludge having active biomass (MLSS) to increase the efficiency of the system to ensure that the effluent quality meets the stipulated PCB (Pollution Control Board) standard.

- Tertiary Treatment: After final sedimentation, overflow water is collected in an intermediate tank and pumped through the PSF and the ACF for further purification and disinfection by a proper chlorine dosing system. The final discharge of water (having BOD < 10 ppm) may be reused for gardening, toilet flushing and other cleaning and washing purposes.

The Sevarth USP

- 2-YEAR FULL WARRANTY.

- 4-YEAR FRP TANK WARRANTY (approx. 50 years life span).

- Electromechanical parts, TTP and any other components used are of the best brands, such as Crompton Greaves, Kirloskar, TATA, etc.

- Provision of an online real-time discharge water test report.

- Isophthalic unsaturated resin and glass fibre are used for FRP tanks.

- FRP tanks are multi-layered (usually 4 layers) with a rib-caged structure for more strength, durability and stability for underground installations to sustain soil pressure.

- Reference diagrams, designs and specifications with full technical support.

Please reach out to us for any enquiries and we will get back with the best offer.